Traditionally most actors in the semiconductor industry has transitioned to a new node every 18-24 months, a trend many think may change in the long run. AMD’s new VP Rory Read is one of them and says that AMD has to rethink its its view of new nodes.

AMD spun off its fabs to a separate company together with ATIC; and formed GlobalFoundries since it simply could not afford to keep its own fabs in the future. The launch of both Llano and Bulldozer have been rather painful stories, which is mainly due to poor yields. This has made the new VP rethink, and says that AMD has to change its relation to new manufacturing technologies.

“Now, let’s talk about 20nm and 14nm. I think that we really flying hard in the path of subatomic environments. The price advantages as we move down nodes are starting to wane. The ability to [quickly improve] yields and ramp up our products (which have fixed amount of time) is under exceptional pressure. It costs huge amounts of money. I think we have to be strategic and think about how quickly we go down the node,[…] Just go look at the cost of wafers as you move down those technologies, they are not going down, they are going up! If the yield does not go up, how do you get your return? You have to charge bigger prices. We will get there, we will move down,” Rory Read, vd på AMD

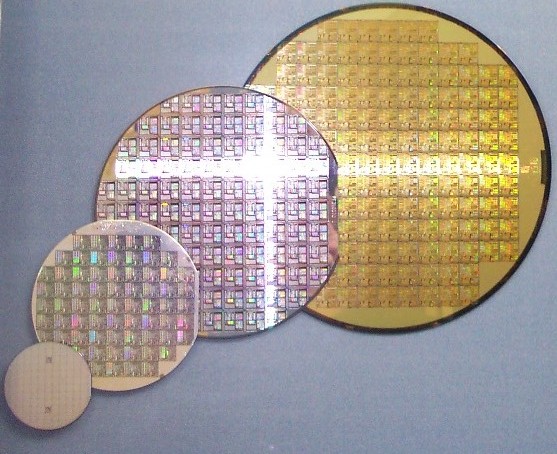

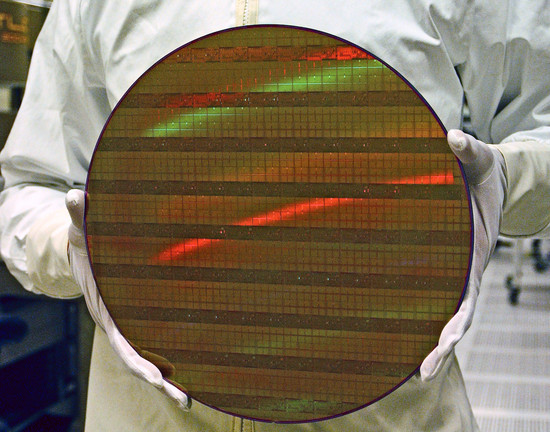

In the past it moved to new nodes not just to get less energy consumption, but also to produce more circuits on a given surface. The big advantage was that you could produce and sell more circuits at a lower price, which isn’t quite true for today. New nodes cost more to develop and the equipment cost more, which forces companies like GlobalFoundries and TSMC to charge more for the wafers. At the same poor yields are far too common, which means few working circuits per wafer. With these factors all put together a more advanced manufacturing technology can become more expensive that staying with a working technology.

“We have some of the best products now! Look at the Brazos chip, over 20 million sold, we think we have taken share in the emerging markets. […] That’s the 40nm process. It is small. It is a beautiful product, it has got great margin. That’s the future! The ability to deliver, to execute[…]Huge set of investments is almost like a chain around your neck. You’ve got to sell gigantic price processors particularly to commercial segment when commercial is nearing the end of the corporate refresh. You’ve got consumerization spreading around the planet. Why are you going down that path? Sure, there are advantages in moving down the node […], there is a lot of profit and opportunity for us in terms of our business. Why moving down the node too fast?”

He continues with the success of the Brazos platform, and it builds on 40nm technology, which makes it possible to sell it with good margins. he doesn’t believe the future lies in having the most advanced manufacturing technology, but using what you have and deliver accordingly. He does not deny there are advantages with more advanced technologies, but there is no need to rush when there is money to make to stick with a proven technology.

What Rory Read says about AMD is already true, or will be in the near future, but also for other companies. The price advantage of a lower manufacturing technology no longer exists, but is instead at a premium. Intel on the other hand will continue with its Tick-Tock strategy – and deliver a new node every other year. Intel is different from most other companies though, thanks to its size and sales figures. Intel can afford to invest in new technologies when selling such huge amounts of circuits.

Source: XbitLabs