GlobalFoundries looks to be holding off on its first fab in Abu Dhabi due to the economic situation in the world, but there are also two other problems that the company has to deal with that puts pressure on the new build: AMD and 450 mm wafers.

ATIC (Advanced Technology Investment Company) is a company directly financed by Abu Dhabi, and it is currently the main owner of GlobalFoundries since AMD now only holds 9 percent of the stock. AMD cannot put a member on the board of GlobalFoundries, which means it doesn’t really have much to say. GlobalFoundries has announced that it will not start building the new fab in Abu Dhabi in 2012, which was the plan at first. It blames the unstable economy, but we suspect more factors are playing a role.

“We will not be engaging in any ground breaking in Abu Dhabi in 2012. Against the backdrop of a global economy still very volatile, we took a decision from a board level that we should not have another facility right now, but we should assess what happens before the end of 2012 on our growth strategy,” said Ibrahim Ajami, VP at ATIC

GlobalFoundries had first planned to initiate the build of the new Abu Dhabi fab in 2012, to open up for manufacturing in 2015. This would be a state-of-the-art fab in the same category as the fabs in Dresden, Germany and New York, USA. It has now postponed the building of the fab in Abu Dhabi and we would believe that it is not just the economy that is the base of this situation.

-

AMD is GlobalFoundries main client, but it recently trashed the two APUs Wichita and Krishna at 28nm – which would have used GlobalFoundries 28nm HKMG Gate-First process. We can also confirm that all GPUs of the HD 7000 series will be built at TSMC at 28nm and not GlobalFoundries. Without AMD it is unclear if GlobalFoundries really needs to increase its capacity.

-

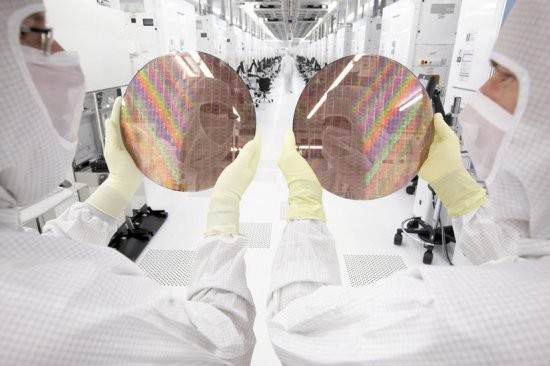

The semiconductor industry is not far from moving from 300 mm wafers to 450 mm. The advantage is 2.25x more circuits per wafer and lower production costs in the long run. In the short run it will bring high investment costs since it will need new equipment for the fabs. It is still unclear when and if the transition will happen, but it will be 450 mm. A fab costs four to five billion dollar to build, and without knowing if it is building a fab for 300 mm wafers, one ready to transition to 450 mm at a later time, or a full scale 450 mm fab it is a huge investment to make.

-

We reported that the business at TSMC is flowering, and it is struggling to increase capacity. It has a new fab that will soon open and several of the older fabs are ready to cross over to 28nm. That GlobalFoundries blames the economy implies its plans to lure over customers are not going as well as planned.

ATIC and GlobalFoundries still intend to open up a fab in Abu Dhabi, but the plans are now back to the planning stages. By the end of next year the final decision for the Abu Dhabi fab will come, whether to build or not.

Source: TheNational